The home of Theo

Simulation software, expert consulting and plant optimization for municipal wastewater treatment facilities

What do we do?

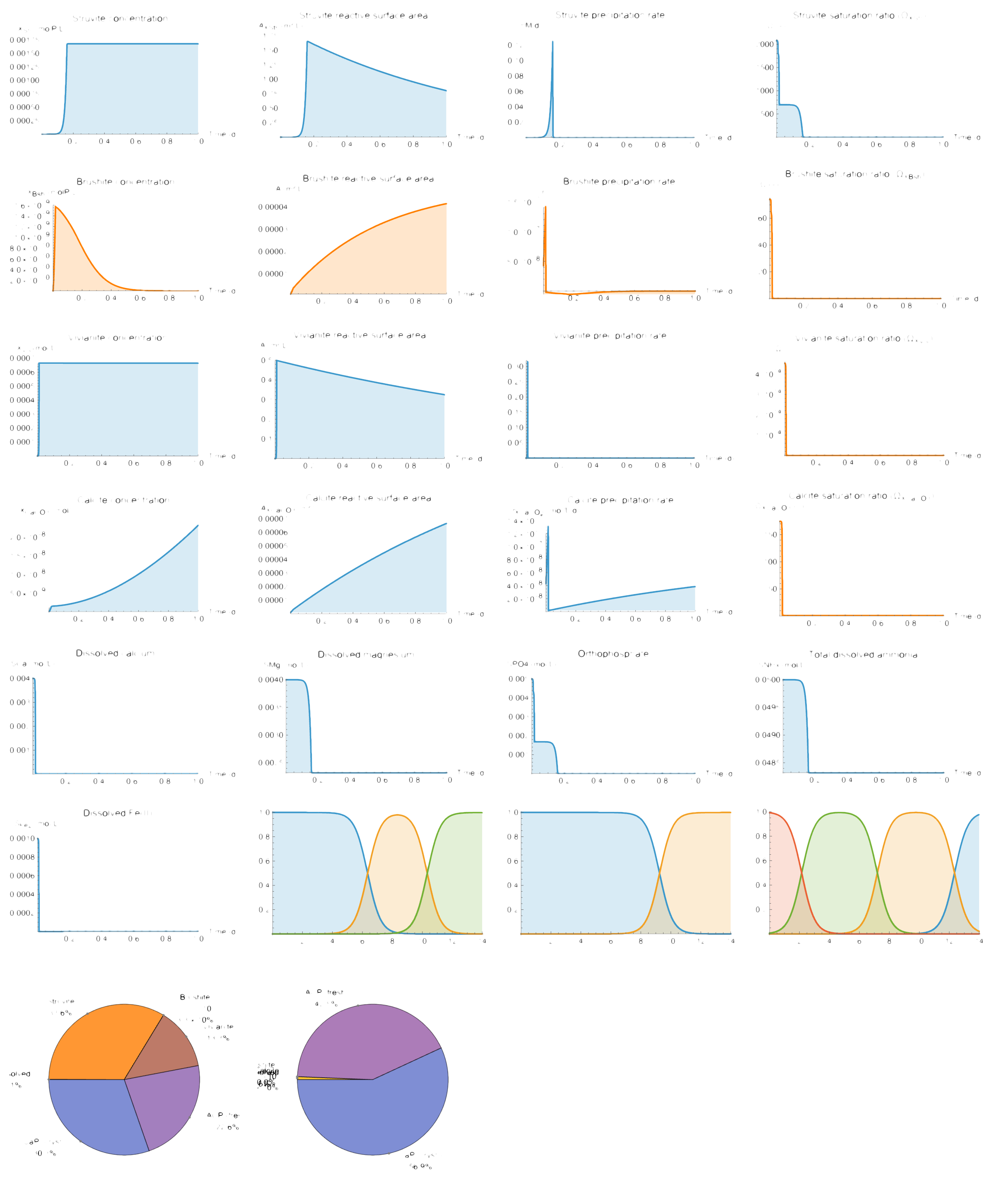

Dynamic Simulation

We develop Theo, the state-of-the-art simulator for wastewater treatment facilities

Process Consulting

Expert guidance on activated sludge processes, nutrient removal, and biological treatment optimization

Plant Optimization

Data-driven strategies to improve efficiency, reduce operational costs, and ensure regulatory compliance

Theo

Advanced dynamic modeling for process optimization and decision support

Modern simulator for your modern hardware

- Platform independent - runs on Windows, MacOS, Linux

- Fast - respecting the rules of model building and leveraging modern numerical methods and hardware acceleration opens up a completely new world - we just started scratching the surface of what's possible...

- Runs completely locally - or in your cloud: you decide

- iOS and Android systems can run the client which connects to your office laptop/desktop/cloud server running Theo

- Stays as close to reality as possible (When was the last time you switched off pH in your plant? Or asked your bugs to do 1 step nitrification only?)

- Tired of user interfaces of the 90s? So are we - Theo features a modern, intuitive interface

- Theo's full plant model is a good mixture of in-house developed experience and published, peer-reviewed models - you stand on the shoulders of giants while still having an unparallelled integration across your entire plant

- We are currently in beta - reach out to become an early adopter and help us shape the future of wastewater treatment simulation!

Consulting

Process Engineering & Optimization

Comprehensive process engineering services focused on biological treatment systems

- Activated sludge process design and optimization

- ASM model calibration and validation

- Nutrient removal system evaluation (N & P)

- Secondary clarifier analysis and design

- SRT and HRT optimization studies

Plant Performance Assessment

Detailed assessments of treatment plant operations to identify improvement opportunities

- Comprehensive plant audits and data analysis

- Operational troubleshooting and diagnostics

- Regulatory compliance evaluation

- Energy consumption analysis

- Process bottleneck identification

Dynamic Modeling & Simulation

Advanced simulation capabilities for informed decision-making

- Custom plant-specific model development

- Scenario analysis for capacity upgrades

- Peak flow and upset condition studies

- Treatment strategy comparison

- Long-term performance predictions

Training & Knowledge Transfer

Specialized training programs to build your team's expertise

- Biokinetic modeling fundamentals

- Simulator operation and interpretation

- ASM model theory and application

- Process control strategies

- Data analysis and interpretation

Who's in Charge?

Let's Talk!

We'd love to discuss how we can help optimize your treatment plant

Contact Information

Address

Nonlineum Labs, 5 Rakoczi St., Fertoszeplak, Hungary, 9436

Teams

robert@nonlineum.com

info@nonlineum.com

Phone

+36 30 945-8739